hardness test usp pdf|hardness definition : importer tests determined. A (USP 1-Aug-2023) weight loss from a single test or the mean of three tests (USP 1-Aug-2023) of not more than 1.0% is considered acceptable for most products. . WEBMelhores Vídeos +18 Vazados do Telegram. [Canal] Hot Novinhas 88.2K members. Melhores Vídeos +18 Vazados do Telegram

{plog:ftitle_list}

cams de Casais. Canais de TV em directo e em português para adultos, ao vivo 24 horas por dia completamente grátis e sempre disponíveis.

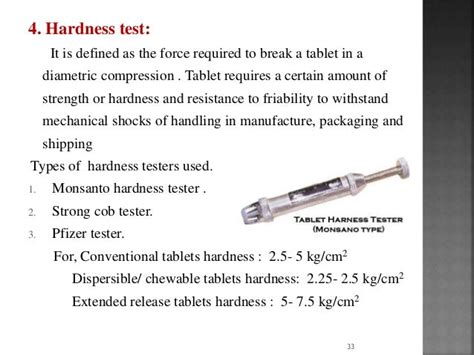

In the Pfizer hardness tester, the vertically mounted tablet was squeezed in a device that resembled a pair of pliers. In the Strong Cobb hardness tester, the breaking load was applied .For conventional, round (circular cross-section) tablets, loading occurs across .Tablet Friability ApparatusFor tablets with a unit mass equal to or less than 650 mg, take a sample of whole tab. ets corresponding to 6.5 g. For tablets with a unit mass of more than 650 .Hardness redefined. The latest revisions now apply to chewable and lozenge formats and reconsider the dissolution, disintegration, friability, and other tests that must be applied to .

tests determined. A (USP 1-Aug-2023) weight loss from a single test or the mean of three tests (USP 1-Aug-2023) of not more than 1.0% is considered acceptable for most products. .For conventional, round (circular cross-section) tablets, loading occurs across their diameter (sometimes referred to as diam-etral loading), and fracture occurs in that plane. The breaking .For these reasons, several tests are available to assess the strength of the compact as well as the response to contact with water and other liquids. These tests include Disintegration .Hardness testing is a simple methodology to interrogate one of the key properties of tablets: the tensile strength. Tensile strength is the value of the stretching force divided by the area .

200 Tablet Hardness Tester Operator’s Manual 2 Introduction Conventions Used in this Manual 14 The 200 is designed to help you easily check the critical physical parameters specified in .Hardness testing > Manual tablet testing system > 8M Tablets are placed in the machine individually and by hand. Practically any imaginable design, including oblong, diamond, .This chapter provides guidelines for the friability determi-nation of compressed, uncoated tablets. The test procedure presented in this chapter is generally applicable to most compressed .

This test involves application of an applied strain (deformation) that increases linearly with time. Some instruments have been designed to specifically measure apparent yield stress using this approach with a vaned rotor (e.g., Brookfield YR-1, yield rheometer); however, this same experiment may also be performed with more advanced rheometers. The units of measurement of tablet hardness are Kilogram (kg), Newton (N), Kilopond (kp), Pound (lb), and Strong-Cobb (SC). . The USP dissolution test in the monograph is related to the Bioavailability and Bioequivalence study only when closely allied with a sound regulatory determination. Without this association, the dissolution test should .Pharmaceutical Testing Hardness T 50 Background: Hardness Testing Together with friability, hardness (or breaking force) is a defining physical characteristic for a tablet. High hardness values may . Chapters Ph. Eur. 2.9.8 Resistance to Crushingof Tablets and USP Chapter <1217> Tablet Breaking Force describestandardised methods for the .

Suggested audience: Tablet breaking force test apparatus manufacturers, tablet press manufacturers. Estimated proposal PF: 43(2) [Mar.–May 2017] Background and objective(s): <1217> Tablet Breaking Force was proposed as a new General Chapter in 2005 and has been part of USP official text since 2007. The General Chapters—Dosage Forms Expert . Model YD-2 fulfils USP <1217> on tablet orientation and 3-point calibration to ensure accuracy in tablet hardness testing. It comes with the calibration procedure as well. Hardness Testing. A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. . EN PDF AT50 – Spare Parts. EN PDF Global Services – Brochure. EN PDF MT50 – Brochure .Hardness Testing. A tablet hardness tester - sometimes also referred to as tablet breaking force tester (USP <1217>) or resistance to crushing strength tester (Ph. Eur. 2.9.8) - measures the mechanical integrity of a tablet. . EN PDF AT50 – Spare Parts. EN PDF Global Services – Brochure. EN PDF MT50 – Brochure .

usp friability chart

USP 1-May-2020-mm holes extend between the ends of the cylinder. One of the holes is centered on the cylindrical axis. The other holes are parallel to the cylindrical axis and USP 1-May-2020 centered 5.8– 6.2 USP 1-May-2020 mm from the axis on imaginary lines perpendicular to the axis and USP 1-May-2020 to each other. FourAll Pharma Test tablet hardness testing instruments are fully compliant to the requirements of the current USP Pharmacopeia. The PTB 311E/511E/311E-800 offers a built-in calibration and validation program for the hardness test station. To validate the hardness test station the PT-MT3 magnetic tablet or different certified weights are used.From standard tablet hardness tests to tensile strength and three-point flexure testing, the MT50 allows to perform different test types in full compliance with USP <1217> "Tablet Breaking Force", Ph.Eur. 2.9.8 "Resistance to Crushing of Tablets" and other harmonized Pharmacopeia.Pharmaceutical Testing Hardness 50 51 Background: Hardness Testing Together with friability, hardness (or breaking force) is a defining . Chapters Ph. Eur. 2.9.8 Resistance to Crushing of Tablets and USP Chapter <1217> Tablet Breaking Force describe standardised methods for the assessment of tablet hardness. Hardness

USP principles for a robust and trusted pharmacopeia. Introduction and background. The United States Pharmacopeia (USP) has been an independent standards-setting organization serving public health needs since it was founded in 1820. Over the two centuries that followed, USP evolved to meet the changing

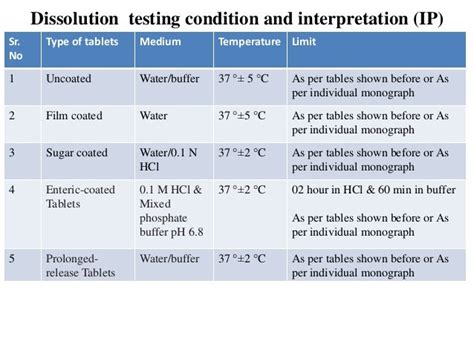

content of active ingredients, hardness test, disintegration test, diss olution test etc. [16]. 3.1. Quality control test for tablets: non-compendial standards

All Pharma Test tablet hardness testing instruments are fully compliant to the requirements of the current USP Pharmacopeia. PT-MT3 for dynamic hardness calibration The PTB111E / 111E-500 / 111E-800 offers a built-in calibration and validation program for the hardness test station. 11. Note: • As per official standard,tablet thickness variation alloted upto (+ or -) 5% of standard value. 4.HARDNESS TEST: • This test is also known as “Crushing Strength Test”. • Tablets require a certain amount of strength, or .

%PDF-1.5 %âãÏÓ 18 0 obj > endobj 37 0 obj >/Filter/FlateDecode/ID[93C29CE3482A3C99420AA066AA540224>67258C49582F2C41BCCF78070A67056B>]/Index[18 45]/Info 17 0 R .(More binder à more hardness) Method of granulation in preparing the tablet (wet method gives more hardness than direct method, Slugging method gives the best hardness). Limits: Oral tablets have a hardness of 4 to 10kg ; but, hypodermic and chewable tablets have a hardness of 3 kg and sustained release tablets have about 10-20 kg.

USP 35 General Information / 〈1216〉 Tablet Friability867 . filled product labeled as sterile must use a system of risk HEPA filter evaluation and testing, as well as routine particu- . take a sample of whole tablets corresponding as near asThe breaking force of tablets is commonly called hardness possible to 6.5 g. For tablets with a .

Hardness of the samples has been evaluated by using Vickers Hardness Test. The Corrosion behaviour of as-received and thermally oxidised samples have been evaluated by using weight loss method.

Hardness testing is a simple methodology to interrogate one of the key properties of tablets: the tensile strength. Tensile strength is the value of the stretching force divided by the area perpendicular to that force at the breaking point or fracture of the material. Units for this quantity are force per unit area which are usuallyERWEKAs hardness testers offer a 100% USP conform solution for every budget and tablet shape. From entry-level manual hardness testing with the TBH 125 to the fully automated, high-volume tester MultiCheck 6 with OblongNavigator for alignment of almost any tablet shape, ERWEKA has your requirements covered. (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.

Tablet Hardness Testing (Breaking Force) From simple hand-held units for use on the production floor, . USP <1217> Max. Tablet Diameter: 36 mm. Force Range: 0 – 490 N. Statistics Reporting: Yes. Batch Testing: Yes. Portable: No. Unit Dimensions (w .PDF | On Oct 13, 2018, Sagar Savale published In Process Quality Control Tests (IPQC) for Pharmaceutical Products | Find, read and cite all the research you need on ResearchGate

View Tablet-Thickness-Diameter-and-Hardness-Test_GROUP3.pdf from PH 20 at Notre Dame of Dadiangas University. Written Report in Pharmaceutical Analysis 2 (Instrumental Method of Analysis) . The Tablet hardness testing instrument Found in USP Chapter <1217> “Tablet Breaking Force” is the preferred term now used in the industry, .Phone: 855-543-3784 or 301-796-3400; Fax: 301-431-6353 . Email: [email protected] are tests that are performed on tablets and which are not listed in official compendia and concern a variety of quality attributes that need to be evaluated, such as the porosity of tablets, hardness or crushing strength test, friability test, tensile .

r box cox transformation

tablet hardness definition

Resultado da Translations in context of "très bon" in French-English from Reverso Context: très bon travail, très bon rapport, un très bon exemple, un très bon ami, .

hardness test usp pdf|hardness definition